Welcome to Our Company

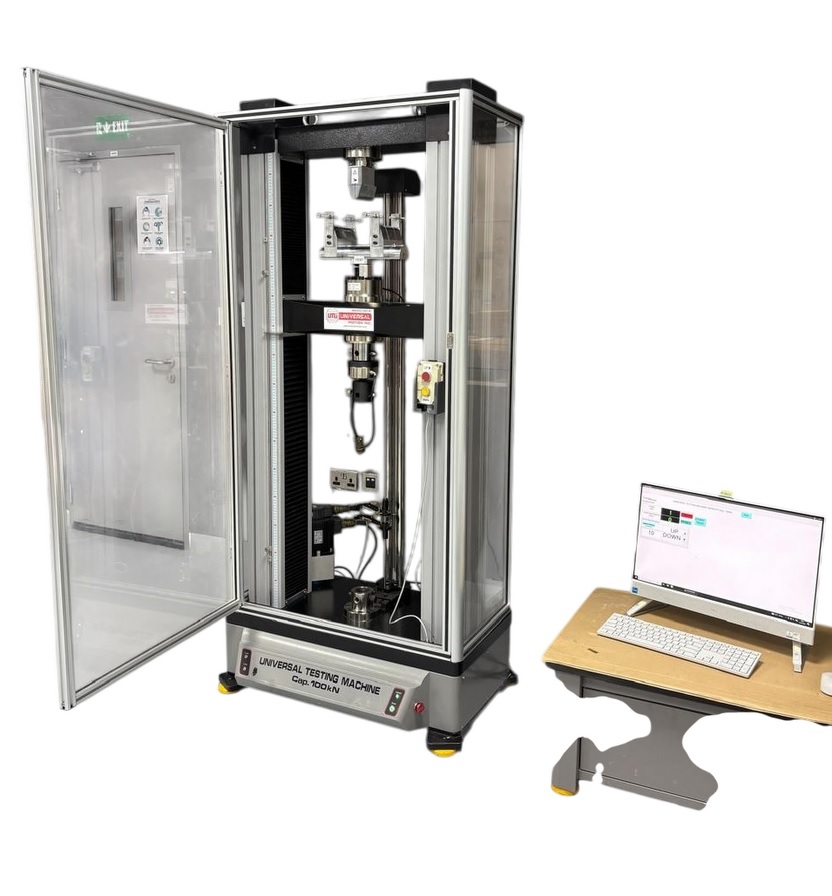

Electronic Pull Tensile Testing Machine

190000 INR/Piece

Product Details:

- Power 220 Volt (v)

- Dimension (L*W*H) 66*45*118 Centimeter (cm)

- Material MS

- Power Supply 220 V, 50 Hz

- Weight 30 Kilograms (kg)

- Temperature 40 Celsius (oC)

- Classification 90248099

- Click to view more

X

Electronic Pull Tensile Testing Machine Price And Quantity

- 190000 INR/Piece

- 190000.00 - 250000.00 INR/Piece

- 1 Piece

Electronic Pull Tensile Testing Machine Product Specifications

- Wire, cable, plastic, rubber, leather, films pull testing

- 10-300

- 350 mm length and 0-7 mm thick Millimeter (mm)

- 220 Volt (v)

- any

- for testing Pull Tensile test

- Electric

- off white

- 50 kgf

- 560 Millimeter (mm)

- 90248099

- ELECTRIC

- 50 KGF Kg/hr

- 80

- Pull Tensile Testing

- 66*45*118 Centimeter (cm)

- 220 Volt (v)

- 40 Celsius (oC)

- 220 V, 50 Hz

- 30 Kilograms (kg)

- MS

- 30 Kilograms (kg)

Electronic Pull Tensile Testing Machine Trade Information

- Pune

- Telegraphic Transfer (T/T)

- 10 Piece Per Month

- 6 Week

- Contact us for information regarding our sample policy

- EXPORT PACKING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Andhra Pradesh, Bihar, Chandigarh, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Chhattisgarh, Haryana, Himachal Pradesh, Madhya Pradesh, Maharashtra, Rajasthan, Tamil Nadu, Telangana, Uttar Pradesh, Uttarakhand, West Bengal

- ISO

Product Description

UMI-Smart, Electric Pull Tensile Testing Machine, move by motor andwith digital push force meter measure unit is mainly used to test plasticsheet, pipe, paper, leather, plastic film and rubber, wire, cable, waterproofcoil, wire and other materials with different fixtures can be measure tensile,compession, bending peel, displacement, tear, inserion and extraction forces,tensile damage and other test, tensile testing machine is ideal testingequipment for industrial and mining, commodity inspection arbitration,reasearch institutes, universities, engineering quality supervisition stationsand other departments.

Versatile Testing for Multiple Materials

Engineered to handle a broad selection of materials, including wire, cable, plastic, rubber, leather, and film, this tensile testing machine suits applications where quality and durability are paramount. Its adaptability ensures consistent and accurate testing, regardless of the material type.

Precision and Flexibility for All Specimen Sizes

With a specimen size capacity accommodating lengths up to 350 mm and thicknesses from 0-7 mm, this machine can test any number of samples efficiently. Its precise test speed control between 10 to 300 mm/min offers flexibility for varied testing requirements.

User-Friendly Operation and Construction

Built from high-strength MS material and weighing just 30 kg, the machine features an electric control mode for easy, reliable operation. Its compact footprint (66x45x118 cm) allows for convenient placement in labs or production areas, while off-white color complements any workspace.

FAQ's of Electronic Pull Tensile Testing Machine:

Q: How does the Electronic Pull Tensile Testing Machine operate?

A: The machine utilizes an electric control mode that allows users to easily set test parameters such as speed and force. Simply secure the specimen, adjust your settings, and the machine performs a precise pull tensile test according to your specifications.Q: What materials can be tested using this machine?

A: This model is designed to test a wide range of materials, including wires, cables, plastic, rubber, leather, and films, making it suitable for diverse industries and applications.Q: When is pull tensile testing typically required?

A: Pull tensile testing is crucial when you need to determine the mechanical strength and durability of materials. It is often used during product development, quality control, and compliance testing to ensure materials meet required specifications.Q: Where is this testing machine best utilized?

A: The Electronic Pull Tensile Testing Machine is ideal for use in quality control laboratories, manufacturing facilities, and research centers where precise tensile measurements are necessary.Q: What is the process for conducting a tensile test with this equipment?

A: Begin by preparing a specimen of appropriate size, secure it in the fixture, set the desired speed and capacity, and initiate the test. The machine will record the force required to pull the specimen until failure, providing accurate, repeatable results.Q: How is the machine powered and what are the requirements?

A: The machine is powered electrically, requiring a standard 220 V, 50 Hz power supply. Its efficient design ensures stable operation in various industrial and laboratory settings.Q: What are the primary benefits of using this tensile testing machine?

A: Key benefits include precise control over test conditions, versatility for multiple materials, and a compact, durable design. These features help ensure reliable, reproducible test results, facilitating high standards of quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email